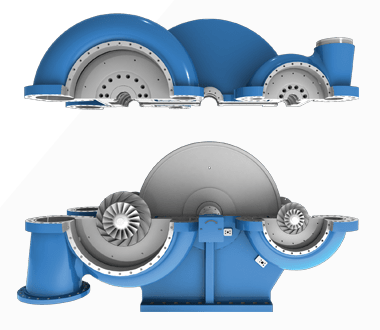

Centrifugal Air Compressors

FS-Elliott is a global leader in the engineering and manufacturing of oil-free, FS Elliott Centrifugal Compressors with operations in over 90 countries. Building on a 60-year tradition of excellence, we combine an unwavering commitment to quality with the desire for advancing technology to bring value to our customers, allowing them to increase their productivity and lower system operating costs

Advantages of Centrifugal Compressors

FS Elliott Centrifugal Compressors also referred to as dynamic compressors, are designed to produce large volumes of compressed air in an extremely energy-efficient process. Although manufacturers that require over 200 to 250 total horsepower tend to realize the greatest savings, all industrial manufacturers should consider the advantages of centrifugal technology.

Oil-Free Compressed Air Stream

The risk of trace oil reaching the finished product or oil contamination in equipment lines leading to higher maintenance and downtime is avoided with a FS Elliott Centrifugal Compressors. Condensate generated from a centrifugal compressor is not subject to the same local regulations as oil-contaminated condensate, allowing for easy and low-cost disposal.

Fewer Maintenance Requirements

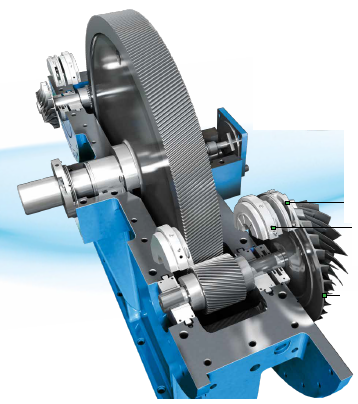

FS Elliott Centrifugal Compressors do not rely on wearing surfaces to create compression, leading to longer-lasting bearings and other rotating components. The number of extra components such as oil and filters are drastically reduced saving material and labor costs. FS-Elliott Centrifugal Air Compressors take maintenance-friendly operation a step further by offering a horizontally split gear case, allowing full access to the gearbox in the field and avoiding costly downtime.

Increased Energy Efficiency

Available in up to four stages, FS Elliott Centrifugal Compressors are on average 5% more efficient than older compressor designs. As the number of stages increases, the compression ratio is lower, meaning higher efficiency.

Oil-Free Air Saves Manufacturing Costs

Certified to deliver ISO 8573-1 Class 0, 100% oil-free air, FS-Elliott’s air compressors are ideal for industries such as food and beverage, pharmaceuticals, electronics, automotive and others that require unpolluted environments.

Benefits of using oil-free air in the manufacturing process include eliminating contamination throughout the plant, resulting in prolonged equipment life, and lowering downstream filtration requirements and pressure drops.

Product Features

- R1000 Control System, featuring a 9-inch full touchscreen display, introduces several new control modes to provide increased energy efficiency.

- Engineered coatings that deliver extended service life, reduce maintenance, and prevent corrosion.

- Mechanically superior bearings that result in improved stability, require less oil consumption, and reduce power requirements.

- Dual carbon ring seals keep the lubricant in the gearbox, ensuring it does not reach the compressed air stream.

- Consolidated package upgrades, providing increased package flexibility, additional future upgrade consideration, and extended product life.

- Advanced aerodynamic staging that reduces power consumption.

- Simple, practical design increases reliability and decreases downtime by limiting rotating and wearing parts and accommodating quick field maintenance.

Energy Savings

Aerodynamic Design and Materials

Polaris+ compressors combine optimized aerodynamic stage matching with intercooler efficiencies to reduce power requirements. Stainless steel, 5-axis machined impellers resist corrosion leading to longer product life and providing the highest efficiency in its class. Each impeller features a backward- leaning design that can be precisely controlled to optimize both airflow and Centrifugal Air Compressors. To perfect the aerodynamics of your machine, impellers are custom designed to your specific applications and site conditions.

Mechanically Superior Bearings

Polaris+ compressors feature mechanically superior bearings that require less oil consumption and enable operators to reduce power requirements.

Adjustable Inlet Guide Vane

By controlling the amount of air being compressed (and consequently the power consumed), inlet guide vanes efficiently adjust to plant conditions and load variations to conserve energy

NEW FS-Connect Remote Monitoring

Control System

FS-Connect has been designed to give you visibility of the operational status and performance of your FS-Elliott air compressor. This web-based connection is provided through a cellular 4G connection and provides easy access to compressor monitoring and allows for troubleshooting from the comfort of a remote location. Once FS-Connect is activated, FS-Elliott will also have full access to the monitored compressor data.

Information that can be tracked:

- Operation and maintenance data

- Operation and maintenance reports

- Historical data

- FS -Connect Subscription Plan

- FS-Connected Services

- Certified Security

- Proactive Control System

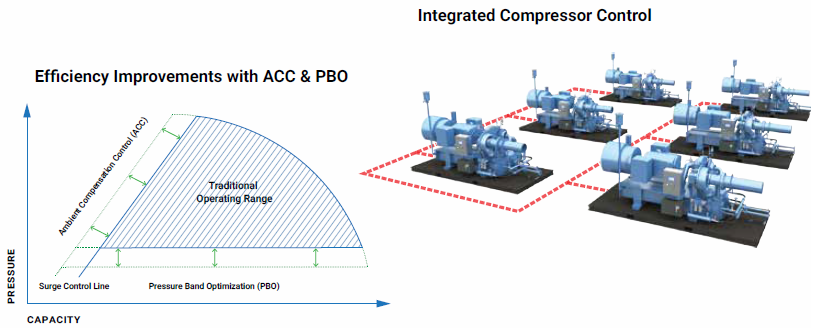

The advanced Regulus Control System, standard on every model, offers flexible control to efficiently manage plant load and maximize energy savings.

- Ambient Compensation Control.

- Integrated Compressor Control

- Pressure Band Optimization

Model P300 Flow: 900 – 2200 cfm (25-60 m3/min) Power: 185-335 KW

Model P400 Flow: 1500– 3400 cfm (45-100 m3/min) Power: 300-600 KW

Model P500 Flow: 2600– 4500 cfm (70-130 m3/min) Power: 450-750 KW

Model P600 Flow: 4000– 6800 cfm (110-190 m3/min) Power: 520-1120 KW

Model P700 Flow: 6000– 12000 cfm (170-340 m3/min) Power: 520-3600 KW

Global Coverage, Local Support

FS Elliott Centrifugal Compressors are designed with field maintenance and service in mind, allowing your plant personnel to perform regular inspection and maintenance or choose to work with a local factory-trained and certified distributor service team. Backed by over 60 years of centrifugal compressor expertise, our global network of personnel and facilities are ready to address your service needs quickly and professionally. From initial design and installation to timely upgrades in step with your evolving needs, we are committed to keeping your vital operations productive, optimized, and reliable.

![]()

Efficient Installation and Start-Up

![]()

Remote Technical Service

![]()

Timely Accurate Repairs

![]()

Essential Preventive Maintenance Made Easier

Auxiliary Upgrades

![]()

OEM Equipment Overhaul

![]()

Training

![]()

24/7/365 Parts and Service Availability

![]()

Extended Value Through Machinery

Modernization (Upgrades/Rerates)Availability

Model P300

Flow: 900 – 2200 cfm (25-60 m3/min)

Power: 185-335 KW

Model P300

Flow: 900 – 2200 cfm (25-60 m3/min)

Power: 185-335 KW Model P400

Flow: 1500– 3400 cfm (45-100 m3/min)

Power: 300-600 KW

Model P400

Flow: 1500– 3400 cfm (45-100 m3/min)

Power: 300-600 KW

Model P500

Flow: 2600– 4500 cfm (70-130 m3/min)

Power: 450-750 KW

Model P500

Flow: 2600– 4500 cfm (70-130 m3/min)

Power: 450-750 KW

Model P600

Flow: 4000– 6800 cfm (110-190 m3/min)

Power: 520-1120 KW

Model P600

Flow: 4000– 6800 cfm (110-190 m3/min)

Power: 520-1120 KW

Model P700

Flow: 6000– 12000 cfm (170-340 m3/min)

Power: 520-3600 KW

Model P700

Flow: 6000– 12000 cfm (170-340 m3/min)

Power: 520-3600 KW