Introduction:

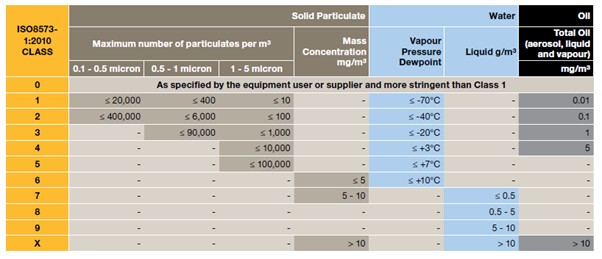

Compressed air quality is a crucial factor in various industries, impacting product integrity and equipment longevity. ISO 8573-1, an international standard, defines the maximum permissible levels of contaminants in compressed air. Understanding the different quality classes (Dust, Water, and Oil) is pivotal in choosing the right compressed air treatment to meet specific quality requirements.

ISO 8573-1 Quality Classes Explained

Class 1 (Dust): Class 1 dictates the maximum allowable particle count in compressed air. This class ensures that the air is free from dust and particulates, vital in sensitive applications like clean rooms and pharmaceutical manufacturing.

Class 2 (Water): Class 2 focuses on moisture content. It specifies the maximum allowable pressure dew point, ensuring the air is dry and devoid of liquid water. This class is crucial in applications where moisture could lead to corrosion or affect the quality of the final product.

Class 3 (Oil): Class 3 outlines the permissible oil content in compressed air. Even minute traces of oil can be detrimental in applications such as food processing and electronics manufacturing. Class 3 ensures oil-free air, safeguarding products and processes.

Matching Compressed Air Treatment to Quality Needs

Dust (Particulates) Removal: To meet Class 1 standards, a combination of pre-filters and after-filters is essential. Pre-filters remove larger particles, while after-filters capture smaller ones. Regular maintenance and timely filter replacements are crucial to maintaining air quality.

Water (Moisture) Removal: Achieving Class 2 standards requires the use of refrigerated dryers or desiccant dryers. Refrigerated dryers reduce the air temperature, condensing moisture for removal. Desiccant dryers Supplier in UAE, with their adsorption capabilities, ensure ultra-low dew points, ideal for critical applications.

Oil Removal: To attain Class 3 standards, coalescing filters and activated carbon filters are employed. Coalescing filters trap oil aerosols, while activated carbon filters adsorb vapor-phase hydrocarbons. Regular monitoring and filter replacements are essential to prevent oil contamination.

Conclusion:

Understanding ISO 8573-1 standards and the specific requirements of each quality class is fundamental in selecting the right compressed air treatment. By matching the treatment method to the quality needed, industries can ensure their compressed air systems meet international standards. Regular maintenance, proper monitoring, and timely filter replacements are key to sustaining air quality, safeguarding products, processes, and the reputation of the industries they serve.

Reach out to us to discuss more:

Let us be your trusted partner in optimizing your compressed air system. For personalized advice tailored to your specific application and requirements, don’t hesitate to reach out. Contact the AES Team, your dedicated experts in, your dedicated experts in compressed air solutions for UAE & Qatar,

Contact Us Today:

Email: adroit@adroit-aes.com