Industrial Nitrogen Gas Applications

Nitrogen is generally used for three main functions:

- It prevents microbial growth or acts as a filler gas in food applications

- It prevents slow oxidization of products such as chemicals and metals during processing or heating

- It prevents rapid oxidization of products that are flammable or explosive with nitrogen generators.

Industrial Segments

- Pharmaceutical

- Food and Beverage

- Laser Cutting

- Laser Sintering

- Laser Ablation

- Laser Eye Surgery

- Heat Treatment

- Fire Prevention and Archive Protection

Nitrogen Gas Generation – Typical PSA Installations

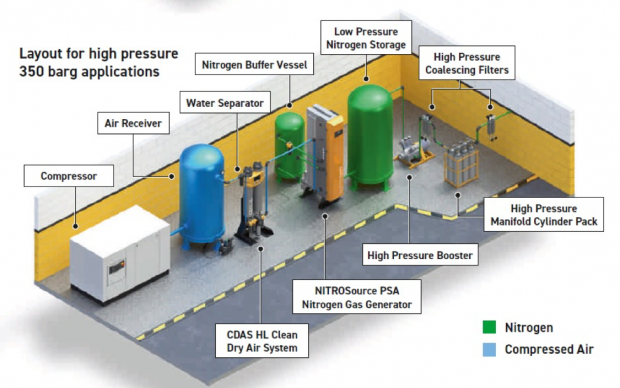

Nitrogen Gas Generation – High Pressure Industrial Applications

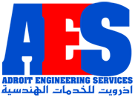

Nitrogen Generator Applications

The use of these innovative gas systems eliminates the usual problems experienced when handling traditional gas cylinders. Running a nitrogen generators costs less than using gas cylinders and can be used in many diverse applications such as:

Oil and Gas: Offshore inerting, instrumentation purge, seal purge, pipeline purging & pigging, and more.

Marine Marine: Flammable cargo inerting and transfer, diving gases, LNG and LPG, perishable inerting, cargo padding, and more.

Food Storage: Packaging, oxidation control of perishable food, sparging of liquids, beer dispensation, etc.

Chemical Processing: Inerting flammable chemicals and fluid transfers, line purging, vessel purging, pressure testing, and more.

Metallurgical and Composites: Annealing, carbonizing, hardening, sintering, mining, laser cutting, wave soldering, etc.

Material Handling/Storage: Silo inerting, fluid transfer, tank inerting, rust prevention, etc.

Laboratory/Electronic/Other: Laboratory gas for purging, tire filling, electrical cabinet purge, inert processing/storage, and more.

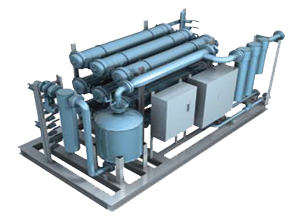

NITROSource PSA Nitrogen Gas Generator

Purity Ranges : 5 ppm to 5%

Flow: 3.5 m³/hr to 155m³/hr

Nitrogen Membrane Modules

AES offer Generon® nitrogen generator which are increasingly relied upon for nitrogen delivery because they are easily installed and calibrated. These nitrogen generators are designed to create, or generate, nitrogen, which is a clean, dry gas for use in many different industries.

AES offer Generon® nitrogen generator which are increasingly relied upon for nitrogen delivery because they are easily installed and calibrated. These nitrogen generators are designed to create, or generate, nitrogen, which is a clean, dry gas for use in many different industries.

There are many different features available with Generon® nitrogen gas generators, including maintenance-free operation and shut-off buttons or alarms.

The latest technological advance in these generators is the use of cryogenic air distillation, which is a method used to generate nitrogen. For this method, air is compressed, and then purified within the generator where it is then cooled within a special unit. As the air runs through the nitrogen generator’s air filters, it is purified and cooled down even further. The oxygen and nitrogen are separated within the oxygen liquid, as the oxygen remains on the bottom while the nitrogen stays at the top. This entire cryogenic air distillation process allows the generators to replenish themselves without the need for manual input, since the liquid nitrogen is mixed into that which has already been produced.

Nitrogen Generators can be used in the following industries:

- Oil and Gas

- Marine

- Food Packaging

- Chemical

- Industrial

- Automotive

- Mining

- Aerospace

- Heat Treatment

Nitrogen Generator Types

AES offer two types Nitrogen Gas Generator:

- Pressure Swing Adsorption (PSA) type with nitrogen purities to 99.999%

and - Membrane type with nitrogen purities from 90% to 95%

IGS Generon Nitrogen Generators offers highly economical nitrogen generator and systems from small portable nitrogen gas generator units to large tonnage nitrogen plants suitable for refining, chemical processing and other applications. Low investment costs and low energy consumption are benefits of our nitrogen generators, guaranteeing a solution for every situation.

On-Site Nitrogen Generator Systems

IGS Generon on-site Nitrogen Generator systems produce a dependable and economical supply of nitrogen allowing you to generate, on-site, the quantity and purity of gaseous nitrogen necessary for most any application.

-

Most efficient separation systems with significant savings over traditional liquid supply methods

-

Product Flow Rates from 10 Nm3/h (40 – 240,000 scfh) @ 95% purity

-

Pressures to 690 barg (10,000 psig) w/ post compression

-

Highest purity – system designed to economically supply nitrogen up to 99.9%

-

Dew Points to -70°F atm

-

Gas streams free of hydrocarbon contaminates to less than 5 PPB

-

Proven technology – over 50,000 membranes sold to date

-

Global network to supply and service our products

-

Extensive engineering resources to meet your customized designed requirements

-

Systems designed with telemetry to remotely monitor and operate from our design centers or yours

-

Optional back-up available to meet your every security need

Skid Mounted Nitrogen Gas Generators

-

Skids are designed with a small footprint to fit into any standard mine shaft

-

Supply pressures 100 – 500 psig standard

-

Field tested and proven design to ensure long system life with over 1,000 systems in operation in every conceivable environment

-

Nitrogen dew point -70°F

-

Fully automatic Nitrogen purity control

-

Systems supplied with certified Oxygen Analyzers and Nitrogen Flow Meters for accurate monitoring and control

-

Systems can be supplied with remote operational control and monitoring

-

Built for all 3rd Party certifications, i.e. NIOSH, MSHA, all Classified areas for Explosive Gases and Dust Environments

Skid Mounted Nitrogen Generators for use in Oil & Gas industry applications.

View the Generon website for more information www.igs-global.com